After a fairly nice spring week with temperatures in the 60s much of the time last week, it’s finally getting to the point where some outside work can start. This past weekend was a busy one.

One of the items on the agenda for this spring is to do some initial work on the landscape design we had created last summer. A week or so ago we got a bunch of diseased or badly shaped trees removed from the property. We have a lot of specific trees and spots in the plan, so it will be easier just to start over with exactly what we want. We’re planning to test a few evergreens for our windbreak and may also start planting along the driveway. I also ordered some smaller shade and decorative trees from Arbor Day just to see if I can get any of them to take off. They come very small and will take a long time, but the cost is significantly less than buying 3-4 year old trees. So we’re hoping to do a mix of more established plantings and let some things take a bit longer.

Another spot I am prepping this year is the front of the house. We plan to put up bushes in front of the porch (probably something like Red Twig Dogwood or Miss Kim Lilac). We’re also going to re-do the walkway from the drive to the porch and extend the perennial beds to flank both sides of the walk. I made a good dent in the prep over the weekend and here’s what it looks like so far.

Here is the spot for the revised walkway and perennial beds. The tulips are already poking up from a smaller bed against the house that we started when we moved here.

Here is in front of the porch. I’m trying cardboard on one side and using the tiller on the other side. Tiller is faster, but a lot more manual labor.

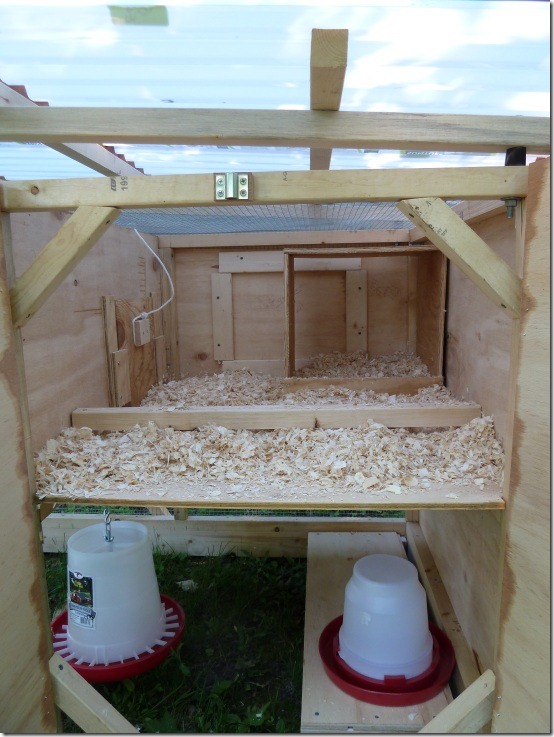

In addition, I’m moving an existing raised bed over to the other side of the garden and attempting to clear a spot for the small greenhouse I bought this spring. Unfortunately the ground is still very mucky and wet, so it’s still too sloppy to use as a base for a structure. Based on how our ground is, I’ll probably have to put down some stone and/or gravel to get a good base.

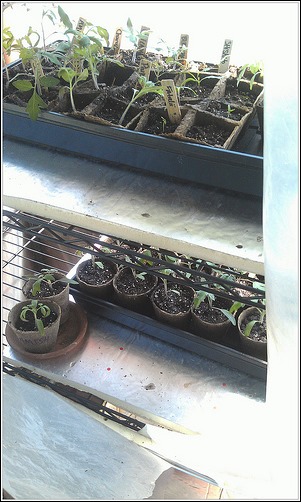

We also continue to get seeds and transplants into the ground, so far just cool weather loving plants like greens, brassicas, etc. The garlic and shallot are poking up above the soil. No asparagus yet and the strawberries are still mulched. Peas are getting sprouted indoors again and Ezra was excited to get to plant some of the snow peas this weekend. The herb spiral is now cleaned up and fresh soil added. Still not sure if some of the plants survived the winter, such as rosemary, thyme, sage and lavender. Hoping the heavy straw mulch did the trick.

I put together one of the hop poles as outlined in the Planet Whizbang Idea Book for Gardeners by Herrick Kimball. I think it should work pretty well for hops at a backyard gardener level. If we ever get more into real hop growing, we’ll need real hop support poles. But this should be fine for now.

The front garden is more dry than the back garden, but both are still too wet to plant. I tried to run the tiller on Saturday, but was only able to get a couple of runs in before giving up. It kept clogging up and it’s just not good for either the tiller or the soil when it’s like that. Got a couple of the dryer sections done though, so that will make room for a few things. We still have at least a month here before typical last frost, so no reason to rush. It’s supposed to turn colder again this week, but I imagine the week after that will be busy again as we have apple trees, cherry trees, raspberries and those Arbor Day trees all coming within the next month.